The importance of a good work ethic

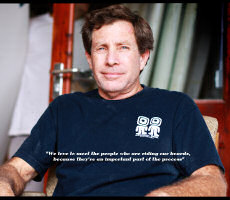

In the commercial and industrialised operation that global surfboard production has become, the value of people and community have largely been lost. Recently we had the opportunity to chat to Malcolm Campbell, the creator of the Bonzer (a Drift feature is on its way), about his views on the globalisation of the surfboard industry. Words: Steve Croft & Mark Sankey, photos: Alexa Poppe.

In the commercial and industrialised operation that global surfboard production has become, the value of people and community have largely been lost. Recently we had the opportunity to chat to Malcolm Campbell, the creator of the Bonzer (a Drift feature is on its way), about his views on the globalisation of the surfboard industry. Words: Steve Croft & Mark Sankey, photos: Alexa Poppe.

Over the years the Campbell brothers have been indirectly approached by some of the world’s largest board manufacturers, but they have always stuck to their principles of hand-built surfboards – high production values, low turnover of goods. When asked for his views on the current trend to mass-produce surfboards in the Far East, Malcolm replied, “We believe in the decentralisation of production. Instead of having all the boards made in one place and then distributed around the world, we believe in coming out to places like England and working with local people. You can have the boards produced locally, so you’re giving something back to the community which is supporting you.”

With the market overflowing with imported epoxy composite surfboards and some of the surfing world’s big-name shapers backing them, has Campbell ever been tempted to go down that route? “I do not think those boards perform as well. Polyester – or even a custom EPS – perform better than the equivalent composite board. Some of it’s to do with performance, but it’s more really to do with our theories of business and community. I would rather give work to guys in the area where people are buying the boards.”

With the market overflowing with imported epoxy composite surfboards and some of the surfing world’s big-name shapers backing them, has Campbell ever been tempted to go down that route? “I do not think those boards perform as well. Polyester – or even a custom EPS – perform better than the equivalent composite board. Some of it’s to do with performance, but it’s more really to do with our theories of business and community. I would rather give work to guys in the area where people are buying the boards.”

This people-centric philosophy is fundamental to Campbell’s approach to surfing and is shown in their logo – two figures representing people and the community. “We are really into design and really into surfing but the thing that has kept the Bonzer going is that it works for average surfers; if it didn’t then it would have died out. We really stuck with it because we want to give something back to surfing because it has given so much to us. We believe in the design but we also want to contribute to the surfing community.”

This people-centric philosophy is fundamental to Campbell’s approach to surfing and is shown in their logo – two figures representing people and the community. “We are really into design and really into surfing but the thing that has kept the Bonzer going is that it works for average surfers; if it didn’t then it would have died out. We really stuck with it because we want to give something back to surfing because it has given so much to us. We believe in the design but we also want to contribute to the surfing community.”